Highest Production Standards

We follow up our strict quality control systems. From raw material to the production process, every step is carefully manage to ensure that our products meet the highest standards. We set extremely high standards for production. We also require our suppliers to follow our standard with raw materials, and ensure they meet our quality standards.

End-to-End Quality Control

Buckingham adopts the APQP (Advanced Product Quality Planning) system, which includes control planning and measures from product concept design to mass production. Through advanced planning and management, we are able to identify the potential quality issues, thereby reducing risks during product development and production processes, controlling production processes.

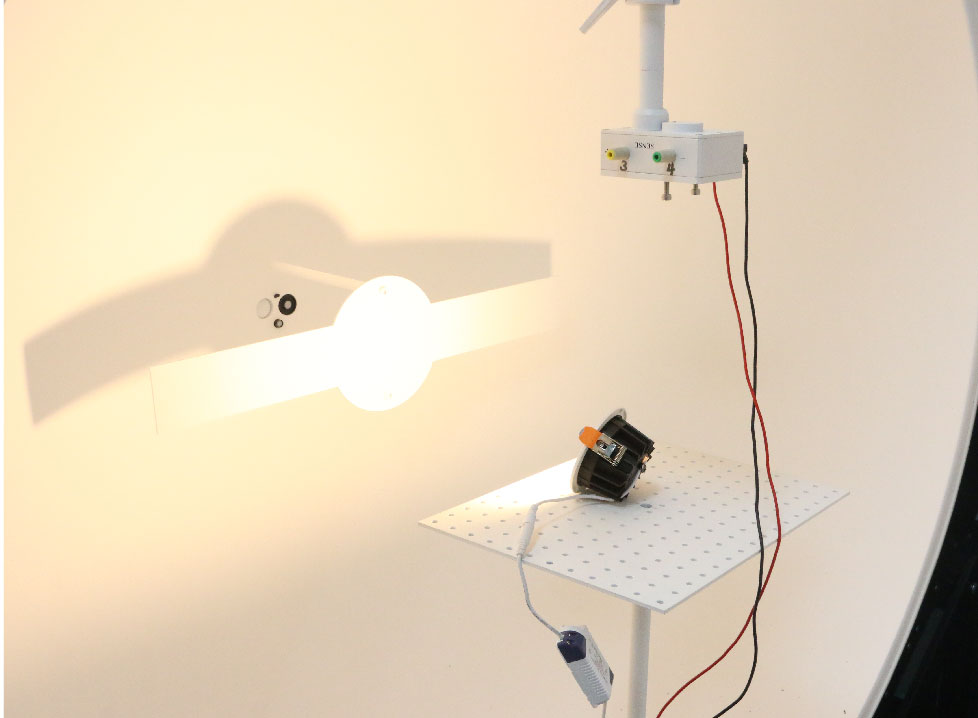

QC Laboratory

Buckingham's quality laboratory covers whole product development and production process. From the inspection of raw materials to the quality control of the final product, we are able to conduct precise testing and analysis. This includes electronic component performance testing, dimensional testing, durability testing, and more, ensuring that each product meets our quality standards. In addition to routine quality inspection work, our quality laboratory actively participates in product development and improvement processes to provide valuable data support and technical advice through testing and analysis, This helps our R&D continuous product improvement and innovation.

Committed to Quality

Buckingham's commitment to quality is unwavering, continuously refining production processes. We keep introduce the latest technologies and methods to enhance our employees' quality awareness. We encourage employees to actively participate in quality improvement to ensure that our products always in a leading position. Buckingham's commitment to quality and full-process control is the key to our success. We strive to ensure that every product meets customer requirements and expectations.