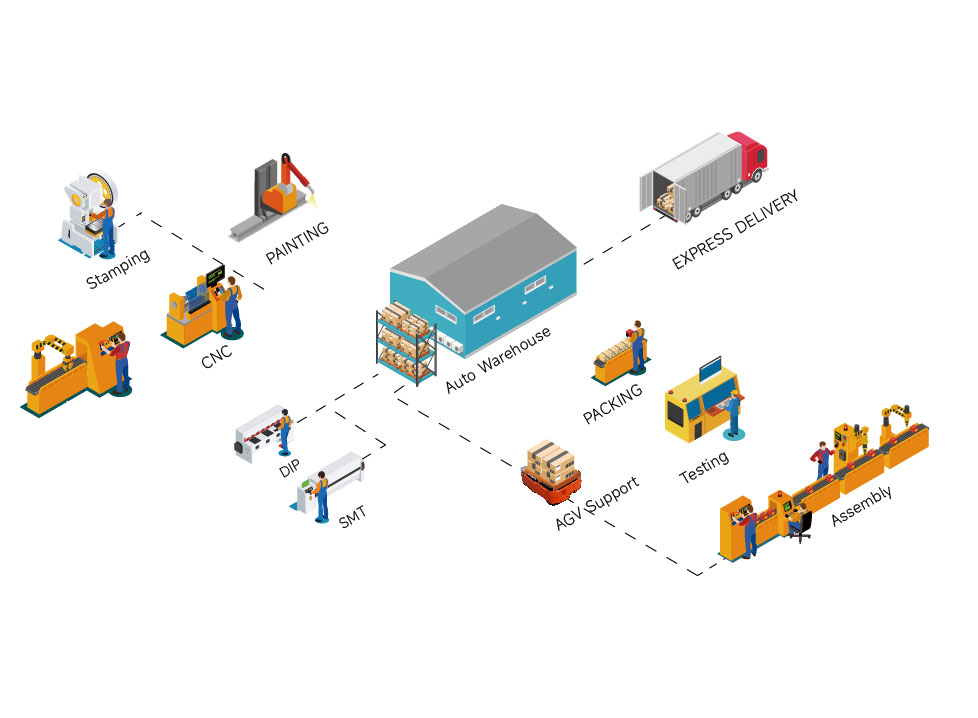

Integrated Manufacturing

Buckingham possesses a distinct competitive advantage in the industry due to its outstanding vertical integration manufacturing capability. We are well-versed in every detail of the manufacturing process, tightly linking design, development, raw material procurement, production, assembly, and delivery to create a seamless production flow. By eliminating unnecessary waste and delays, we enhance production efficiency and adapt more flexibly to changing market demands, ensuring the highest level of products and services for our customers.

Buckingham boasts advanced production facilities that encompass everything from raw material processing to final assembly, including die-casting, stamping, CNC machining, painting, SMT, and DIP. This allows us to oversee every stage of the production process, ensuring product quality and delivery time, achieve maximizing production efficiency and quality. Our production team consists of industry experts with extensive experience and professional knowledge. They collaborate closely with the research and development team to continually optimize various production solutions to meet the needs of our customers.

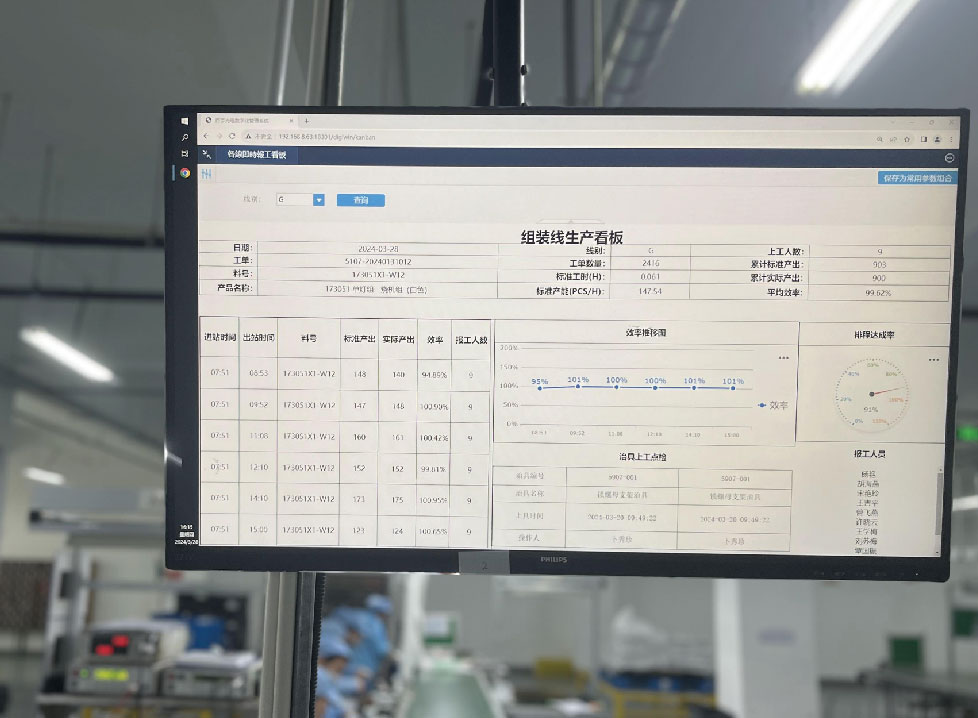

Digitalized Management

Buckingham has been committed to leading innovation in the manufacturing industry. In 2019, by upgrading our ERP system and implementing Manufacturing Execution Systems (MES), Warehouse Management Systems (WMS), Human Resources Management (HR), Business Process Management (BPM), and Business Intelligence (BI) systems. These efforts were aimed at further optimizing our operational and management processes, achieving digitalized management of production operations, enhancing efficiency, reducing costs, and strengthening competitiveness, all to deliver superior products and services to our customers.

Through the upgrade of our system, we integrated processes across different departments to facilitate seamless information flow and data sharing, thereby improving production and operational efficiency. We enhance our data analysis capabilities, enabling us to better utilize data analysis to understand market trends, customer demands, and overall business operations, thus making more informed decisions.Throughout the process of digitalized management, we prioritize information security and compliance requirements. Through the implementation of security measures and compliance standards within our systems, we ensure the security and privacy of both our company and customer data.

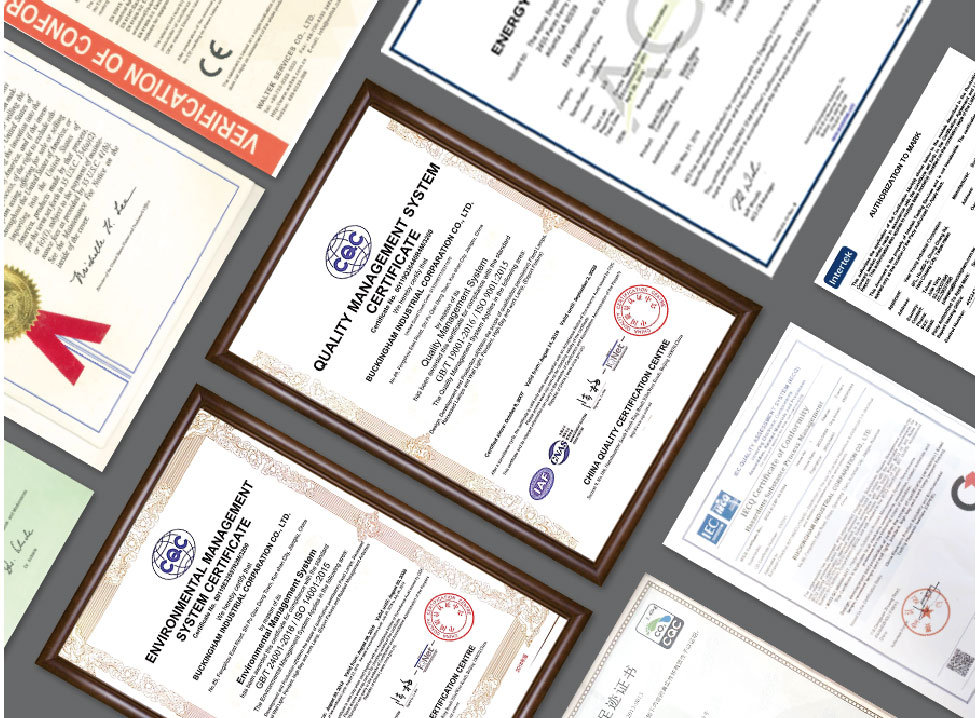

Certifications and Compliance

Buckingham has always been committed to high-quality, environmentally friendly, and safe production. We hold multiple important certifications such as ISO9000, ISO14000, QC080000, and Carbon Footprint. These certifications not only represent our commitment to quality, environmental protection, and safety, but also embody our competitive advantage in the industry.

Through these certifications, Buckingham ensures the optimization and continuous improvement of our production processes, thereby providing high-quality products that meet customer expectations. Buckingham's commitment to environmental protection is reflected in our production processes, where we take various measures to reduce energy consumption, minimize waste generation, and lessen our impact on the environment, ensuring the sustainable development of our business. We will continue to strive for excellence, continuously improve ourselves, and contribute to achieving sustainable development.