New Factory in Thailand Today, Buckingham has intensified its global layoutto face the internationa

Today, Buckingham has intensified its global layout to face the international environments and trends. We have invested in a new factory in Thailand to expand the group's production capacity. With this new investment, we are committed to the sustainable development of our enterprise and the ongoing growth of the lighting industry.

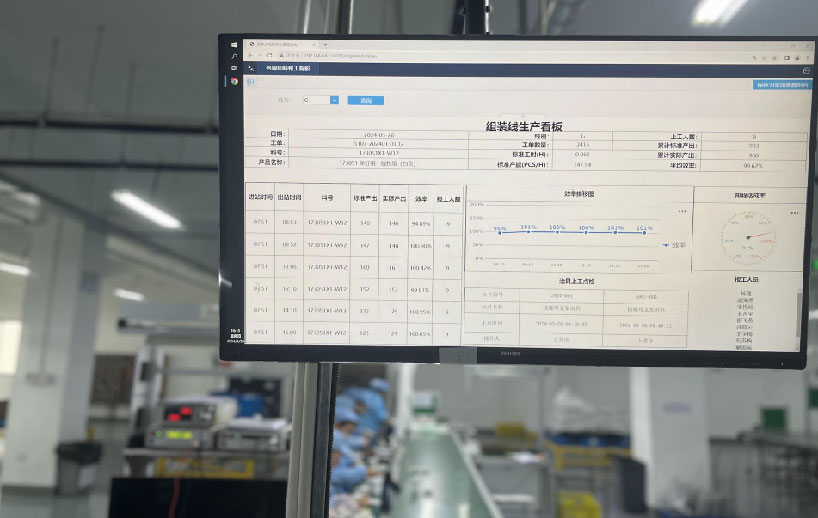

Reach SMART manufacturing system

We follow the trend of intelligent manufacturing. By upgraded ERP, PLM, BPM, MES, WMS etc. Through improved software,we shorten our lead time and production efficiency improvement.

We made a strategic investment in automated warehousing, revolutionizing our supply chain management and enhancing operational efficiency. This strategic move not only streamlined our processes but also positioned us for future growth in the rapidly evolving industry landscape.

This year, we launched factory expansion project to meet the growing demand .Erected 25,000 sqm space building and upgraded facility.This expansion not only amplifies our manufacturing capacity but also underscores our commitment to innovation, sustainability, and delivering superior quality products to our valued customers worldwide.

A milestone achievement in our sustainability efforts,carbon footprint labels proves an important milestone achieved in sustainable development work. Through focused actions and strategic planning, we've minimized our environmental impact while enhancing operational efficiency. This accomplishment reflects our dedication to responsible environmental practices and positions us as a conscientious participant in sustainable initiatives.

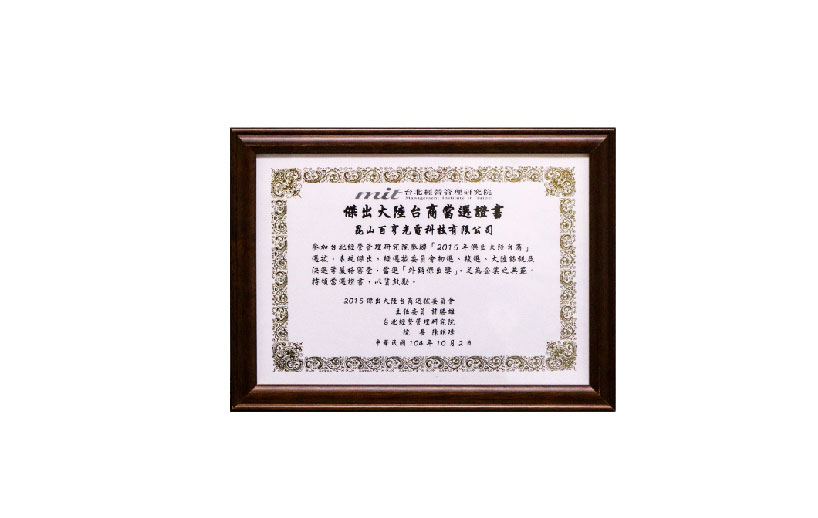

Our company has been honored with the prestigious award for being one of the best exporting companies in Taiwan. This recognition our commitment to excellence, innovation, and dedication to delivering high-quality products to global markets, which highlights the hard work and dedication of our team.

Spun process started in house for lamp shades first sale of Puck lights in retail stores

Started power painting, anodizing and plating in China factory

Established China factory and began hardware and metal process in house. Set up die cast, stamping, CNC, and tooling workshop

Started residential lighting manufacturing

Designed Marcos recessed down lighting patented in US, China and Germany. Great success prompts move to industrial building in New Taipei City.

Introduced new design for table lamp prayer with great response from market. Promoted by rapid growth company moves to new facility focusing on lighting, especially down light and track head

Established Buckingham in Taiwan focusing on lightingbusiness and export to North America.

Manufacturer of painting machinery for motorcycle and hardware parts. Began contract painting service for automobile and electronic components